BELT PRESS

Description

Wide range of Belt Filter Presses to match any plant size, keeping in mind the following key features :

- high quality components (only stainless steel construction),

- low energy consumption and operating cost,

- clean operation,

- operators safety devices,

- easy access for supervision and maintenance,

- visual control of the sludge during dewatering.

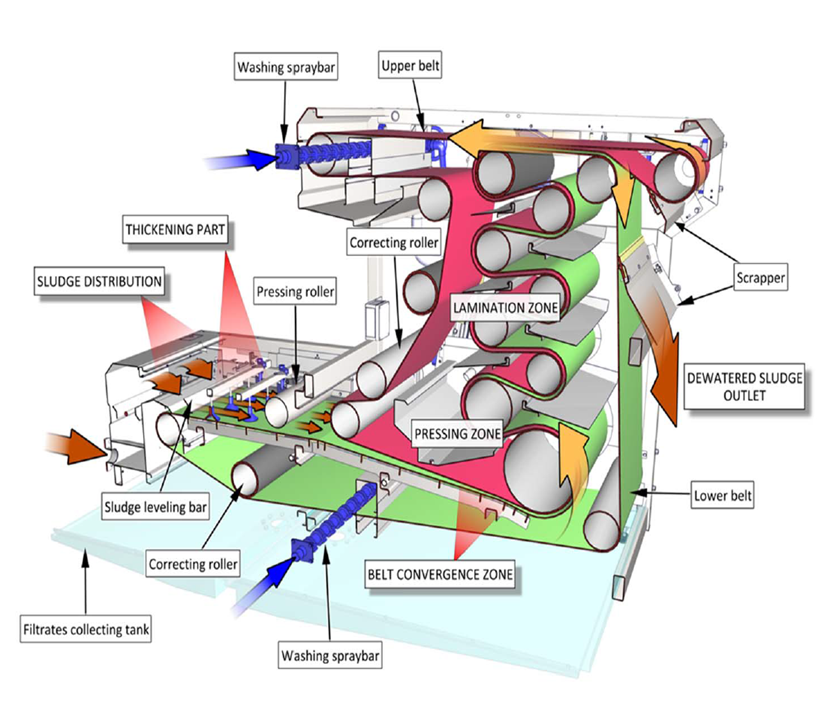

Principle of Operation

- Sludge is conditioned with polyelectrolyte , and sometimes with mineral additives (lime, talc …).

- Flocculated sludge is evenly distributed across the belts then dewatered by compression and shearing effects between 2.

- The filtrate water forced through the belts is caught in tray systems

- The floc must be quite voluminous due to the mesh opening of the belts (to avoid sludge going through the belts) and the floc structure must be

resistant under pressure. - To avoid clogging, filtration belts are washed continuously with clean water, under 7 bar pressure, and considering 6 m³/h per meter of belt

width.

Model